The North Sea is entering its largest decommissioning cycle in history. The UK Continental Shelf (UKCS) will see £27 billion spent taking apart end-of-life oil and gas infrastructure over the next decade [1] creating a remarkable opportunity in the metal recycling sector.

Operators will remove 91,000 tonnes of topsides, jackets and subsea infrastructure between 2024 and 2027 alone [2] the same weight of more than 60,000 average passenger vehicles. The difference being that this material contains high value metals, that include structural steel, copper from electrical systems and specialty alloys from critical components. The primary challenge facing the industry is clear; who has the capability to handle the scale of this work and how will these materials re-enter the supply chain?

Why decommissioning activity is accelerating now

The UK Continental Shelf is getting older – a state that is obvious throughout the statistics. Fields that have produced oil and gas since the 1960s have seen a great number ceasing production entirely. Annual decommissioning expenditure surpassed £2 billion (£2.4billion) for the first time in 2024 [3], which accounted for 15% of total UKCS spending in 2024 [4]. This share is expected to increase exponentially – exceeding 30% as operators prioritise end-of-life asset management over new field development.[5]

This is accelerated by 3 factors:

Regulatory pressures: The North Sea Transition Authority (NSTA) backs prompt decommissioning with tight environmental and safety standards.[6] There are potential financial penalties for operators for any delays – they must prove their management of aging assets is cost-effective.

Economic reality: Taking care of unproductive infrastructure can be very expensive. This becomes apparent in the ongoing inspection, maintenance and safety systems of platforms – even when production stops. When all this is considered, decommissioning becomes the economically sensible choice after all operational lifespan ends.

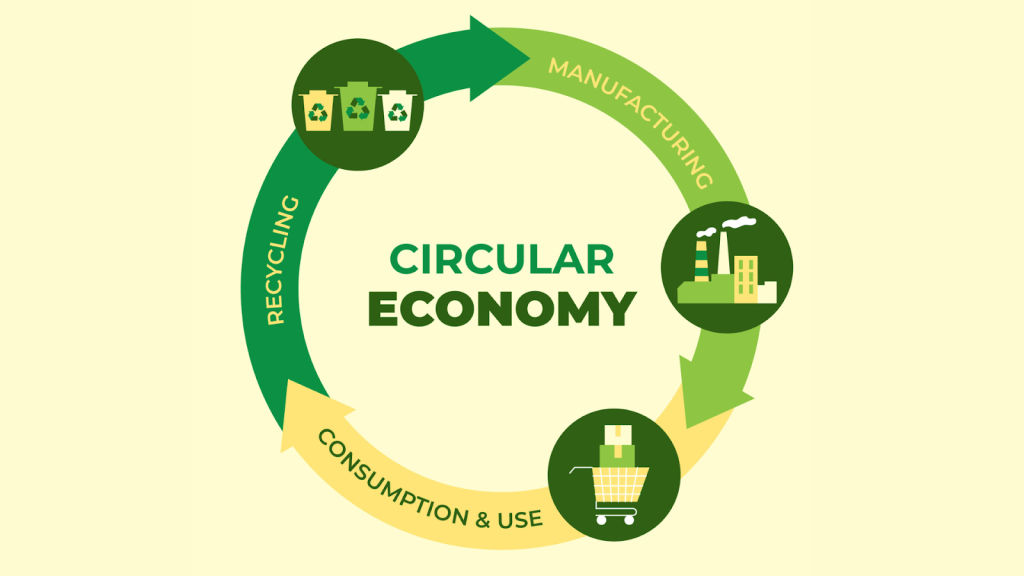

Energy transition: The UK is moving towards renewable energy and net-zero targets, with operators in oil and gas under pressure to clean up their legacy assets. The movement creates obligations, but also opportunities to demonstrate leadership in the circular economy.

What’s the result? A plethora of activity – with a backlog of more than 500 wells plus an additional 1,000+ wells expected to require decommissioning between 2026 and 2030. [7] It’s projected that subsea infrastructure will average 51,000 tonnes annually through the end of the decade. [8] This work will require considerable capital investment and specialised contractors with good track records

Where the value lies: Material composition and recovery potential

When we look at a typical offshore modular production platform that weighs 2,500 – 5000 tonnes [9] it contains:

-

- Structural steel (80-85% by weight – typical composition): This material is typically used for electric arc furnace (EAF) steelmaking – it can be reprocessed into construction-grade steel, rebar, and structural components.

-

- Copper (2-4% by weight): Substantial copper is typically found in electrical systems, control pods, and umbilicals – worth up to £50,000-150,000 per platform at current market prices.

-

- Specialty alloys (5-8% by weight ): Here we find stainless steel, aluminium, and titanium components, often used in applications that are corrosion resistant – these can command premium prices when properly sorted and processed

When we look at the stats, we see the industry has achieved recycling rates of 85%-95% on major decommissioning projects [10]. Shell’s Brent field project, one of the largest to date, reached 98.5% material reuse [11] and recycling across 95,000 tonnes of topsides. BP’s North West Hutton decommissioning achieved 98.34%, with nearly all material either reused or sent for smelting and cold rolling. [12]

These aren’t theoretical figures, they’re operational benchmarks, demonstrating what can be done when decommissioning approaches a resource recovery, rather than just disposal.

What this means for UK metal recycling

The £27 billion North Sea decommissioning cycle is more than just project revenue – this movement will reshape how the UK metal recycling sector operates.

The importance of scale and specialisation: Offshore platform decommissioning can’t be handled by commodity scrap merchants. This is because the work requires special equipment, permits and technical expertise – plus high financial capacity.

The operational reality of the circular economy: The scale of decommissioning forces the wider industry to think beyond simple recycling. Factors like material recovery, sorting, refining, and reintroduction into manufacturing supply chains become standard practice rather than just aspirational goals.

The strengthening of domestic supply chains: UK scrap metal exports are facing potential policy restrictions – at this uncertain juncture, decommissioning provides high-quality domestic material for EAF steelmaking and specialty metal manufacturing.

The companies that are positioned to take advantage of this opportunity are those with integrated capabilities – if they are able to handle decommissioning, land remediation, material processing, and metallurgical refining under one operational framework.

Looking ahead

The North Sea decommissioning cycle will define the next decade of UK industrial recycling. £27 billion in expenditure, 91,000 tonnes of infrastructure removal in the next three years, and recycling rates approaching 95% demonstrate both the scale of opportunity and the operational standards required to succeed.

Peak decommissioning activity runs through 2027 so the window is now. Capacity constraints favour all those already positioned with the right infrastructure, expertise, and regulatory relationships.

Want to learn more about industrial-scale metal recycling and decommissioning? Follow Enicor on LinkedIn for insights on circular economy practices, regulatory developments, and the future of resource recovery in the UK.

[1] – : North Sea Transition Authority (2025). UKCS Decommissioning Cost and Performance Update. https://www.nstauthority.co.uk/regulatory-information/decommissioning/cost-estimate/

[2] – Offshore Energies UK (2024). Offshore Decommissioning Report 2024. Published November 2024.

[3] North Sea Transition Authority (2025). UKCS Decommissioning Cost and Performance Update. “Operators spent a record £2.4 billion on decommissioning in 2024.”

[4] OEUK (2024). Offshore Decommissioning Report 2024; NSTA (2025). Cost and Performance Update.

[5] OEUK (2024). Decommissioning accounted for 12% of total oil and gas expenditure in the UKCS in 2023 but this could increase to 33% by 2030.

[6] North Sea Transition Authority (NSTA). Regulatory information on decommissioning.

[7] NSTA (2025). “A backlog of more than 500 wells which missed their decommissioning deadline has built up…In excess of 1,000 additional wells are expected to be due for decommissioning between 2026 and 2030.”

[8] OEUK (2024). Page 21, Section 3.4 Regional Trends

[9] University of Aberdeen. “Shell Decommissioning of the Brent Platform.” April 2017.

[10] Ingenia (2023). “Decommissioning North Sea Giants.” Discusses BP North West Hutton achieving 98.34% recycling.

[11] Able UK / Shell UK. Brent Field Decommissioning Project – 98.5% recycling achieved. OEUK Awards 2025; Shell UK (2019). Brent Field Topsides Decommissioning Close-out Report.

[12] Ingenia (2023). “Decommissioning North Sea Giants.” https://www.ingenia.org.uk/articles/decommissioning-north-sea-giants